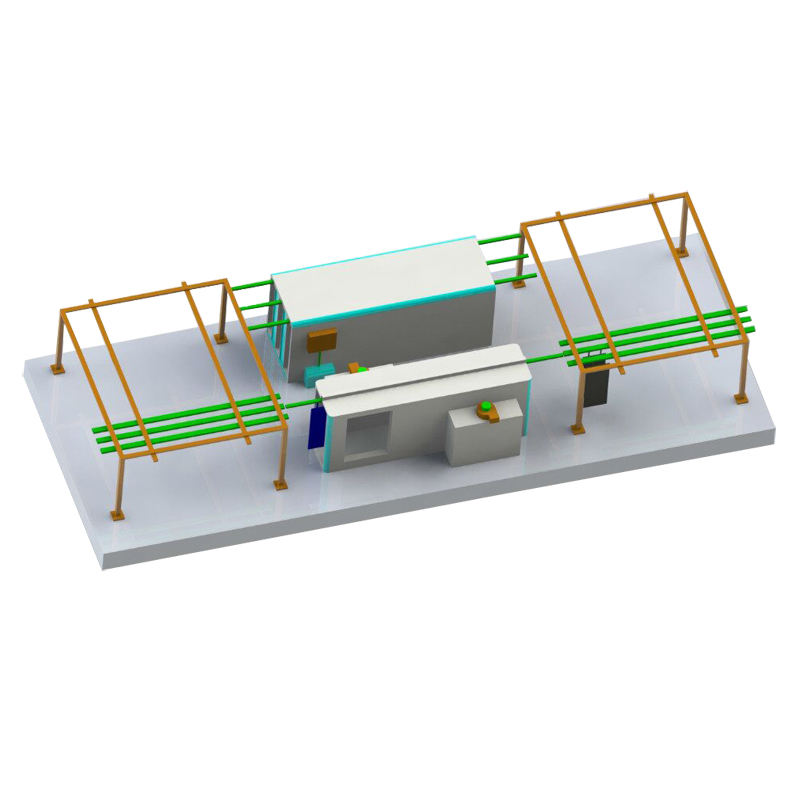

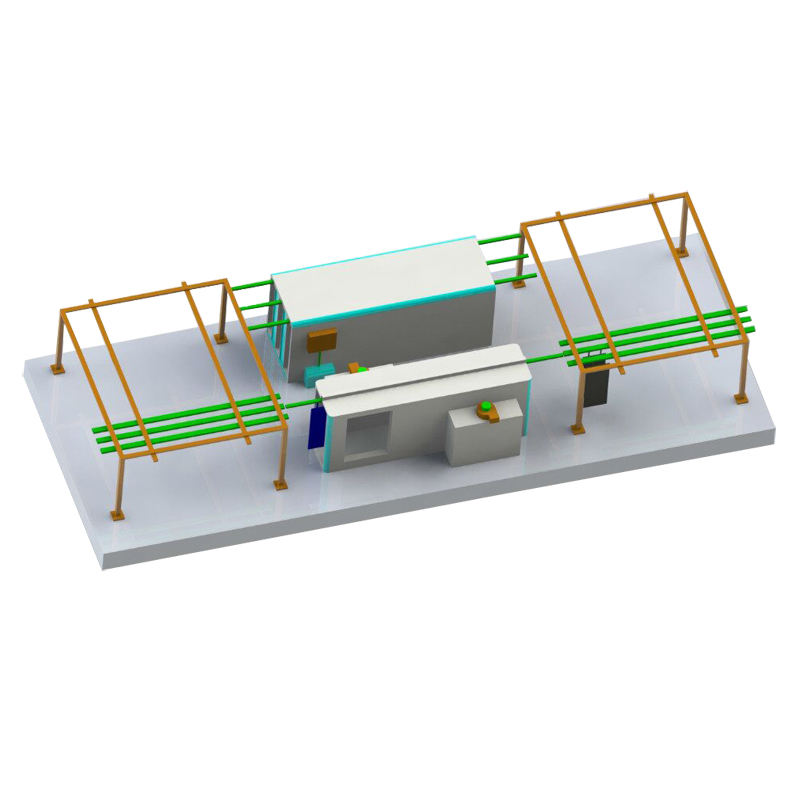

Floor Rail Coating Line Comprehensive Process Flow for Large

Workpieces

The Floor Rail Coating Line offers tailored coating solutions for

heavy workpieces, combining an unpowered

translation vehicle and ground conveyor chain for efficient

handling. The comprehensive process flow includes

sanding, cleaning, drying, spray painting, and baking. Customizable

room structures, including polishing, cleaning,

drying, spray painting, and baking rooms, provide specialized

environments for each stage, ensuring optimal results

and increased productivity.

| Machine Type | Roller Coating line |

| Warranty of core components | 1 Year |

| Core Components | Motor |

| Place of Origin | Guangdong, China |

| Warranty | 1 Year |

| Key Selling Points | Automatic |

| Applicable Industries | Automobile Wheels, Turntables, Ovens Machinery Repair Shops,

Manufacturing Plant, Construction works |

| Weight (KG) | 200 |

| Substrate | Steel |

| Condition | New |

| Coating | Painting |

| Brand Name | CoatTech |

| Voltage | 380V |

| Power | 5KW |

| Dimension (L*W*H) | AS YOUR NEEDS |

| Function | Spraying Coating |

| Color | Customizable |

| Weight | 24kg |

| Voltage | 380v |

| Power | 75kw |

| Size | 24330*6300*3700mm |

| Product name | Roller Coating line-1 |

| Keywords | Painting Line |

| |

| Packaging and Delivery | |

| Selling Units | Single item |

| Single package size | 60X50X40 cm |

| Single gross weight | 50.000 kg |

| Lead time | |

| Quantity (sets) | >1 |

| Lead time (days) | 15 |

Used for surface treatment of large, heavy workpieces with low

productivity requirements;

Process flow:pieces

on-->sanding-->cleaning-->drying-->spray

painting-->baking paint-->pieces off;

The room structure includes: polishing room, cleaning room, drying

room, spray painting room, and baking room

(customized according to the product);

Translation car: It is welded and formed by I-beam and channel

steel, and the surface is paved with 8mm thick steel plate;

Ground conveyor chain equipment description:

It is mainly composed of driving device, traction chain, tensioning

device and conveyor track.

⑴Driving device

The power of the driving device is transmitted to the driving

spindle through the motor-reducer and the transmission chain.

Finally, the driving sprocket drives the conveyor chain, making the

conveyor chain move forward along the conveyor chain track;

the use of a cycloidal pinwheel reducer can greatly improve the

transmission efficiency. , and the movement is reliable.

⑵ Traction chain

The chain consists of pin shaft, chain plate, pusher chain plate

and roller sleeve. The pusher spacing can be assembled into

various shapes according to needs.just to meet the needs of work

rhythm.

This series of conveyor chains all use high-quality manganese steel

as chain plates, and all require specified tensile tests

before leaving the factory.

⑶Tensioning device

This device ensures that the entire conveyor chain always maintains

a relatively stable tension during operation.

At the same time, it can absorb or compensate for the installation

error of the conveyor chain, the expansion and contraction caused

by thermal expansion, contraction and force deformation during

operation. Ensure that the conveyor chain has an initial tension at

the

winding-out point of the drive device and eliminate devices that

generate negative tension in the entire line.This series of

tensioning devices mainly uses screw rods for tensioning. Its

structure is relatively simple and compact, and its tensioning

force is relatively stable;

⑷Conveyor track

The trolley track adopts 30kg/m light rail (the foundation is

pre-embedded in construction), the running wheels use light rail

steel wheels,

and the trolley brackets are all welded from section steel, with a

solid structure;The entire line adopts PLC control, stepless speed

adjustment, and is equipped with multiple induction probes and

control buttons.

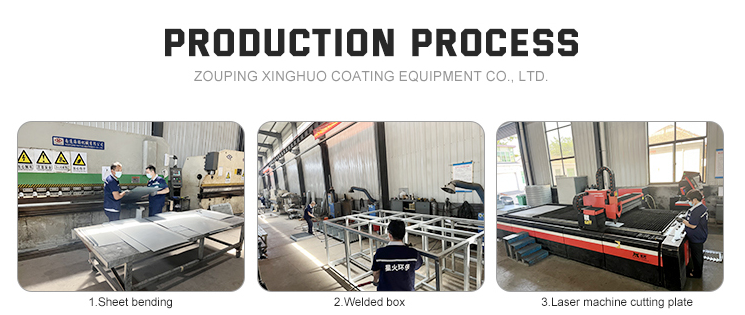

Peace Environmental Protection always adheres to the core principle of "quality first, honest

service" and provides

excellent solutions for customers in the field of environmental

protection equipment. The factory is located in

Guangzhou City, Guangdong Province.

The company's main products include environmental protection

equipment such as spray booth,coating line,painting line

and waste gas and wastewater treatment,if you have any

inquiry,please leave the inquiry here directly,will be respond to

you within 12 hours

We will make the exact Design Drawing,Design Case in words,and

Quotation in detail,just waiting for you leave the message here.